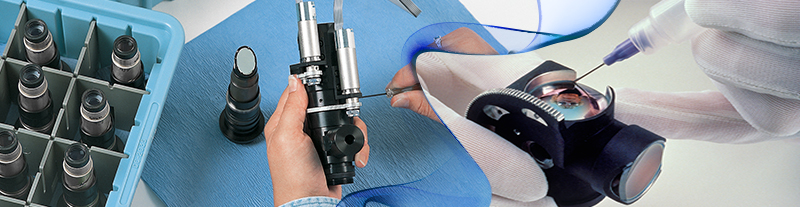

Precision Assembly

Assembly of diffraction limited lens system is equally as important as the polishing of the lens elements themselves. In fact, many times performance degradation is traced to poor lens assembly, not the lens elements. In particular, air-spaces, centration, tilt and wedge are the key determinants of a quality lens system.

Air-Spaces

In high resolution diffraction limited systems, very often it is necessary to measure and maintain lens spacing to the order of a few microns. Not an easy task, but one that we have worked extensively at perfecting. Through the use of micron indicators coupled with proprietary assembly equipment we can hold lens spacing tolerances to the order of 1 micron. This is only possible through constant re-optimization of the lens design during the assembly process.

Centration, Wedge and Tilt

A major challenge during assembly of diffraction limited optics is to maintain the centration, wedge and tilt specifications for the system of lenses as a whole. Simply inserting lenses and spacers into lens tubes is not sufficient or even possible to maintain diffraction limited performance. Over the years we have developed both standard and proprietary techniques for insuring that all tolerances are met.

Assembly Capabilities

-

Air-Space Tolerances Held to 1 Micron

-

Continuous Lens Design Reoptimization During Assembly

-

Centration, Wedge and Tilt tolerances held to Better than 1 Micron

-

Air-Bearing Spindles

-

Laser Alignment

Interferometers: Zygo VeriFire GPI (632.8nm), Zygo Mark II w/Diffraction LTD Phase Shifter (1064nm)

Other: Opti-Pro UltraCurve Sherometer, Wells Research OS400-10 MTF Bench, two Gaertner Optical Benches

Assembly stations: Taylor Hobson Talyrond 250, Custom Built Laser Assembly Alignment Station

Manufacturing Tolerances

| Attribute |

Commercial Quality $$ |

Precision Quality $$$ |

Ultra Precision Quality $$$ |

|---|---|---|---|

| Diameter (mm) | +0.00/-0.10 | +0.000/-0.05 | +0.000/-0.025 |

| Center thickness (mm) | 0.150 | 0.050 | 0.005 |

| Radius (power) | 8 rings | 4 rings | 1 ring |

| Irregularity (waves @ 633nm) | 1 | .25 | .1 |

| Wedge (mm) | 0.05 | 0.005 | 0.0025 |

| Decenter (arc min) | 0.05 | 0.01 | 0.005 |

| Scratch-Dig | 80-50 | 60-40 | 10-5 |

| AR Coating (r avg) | < 1.5% | < 0.5% | < 0.25% |

Next > Testing and Verification