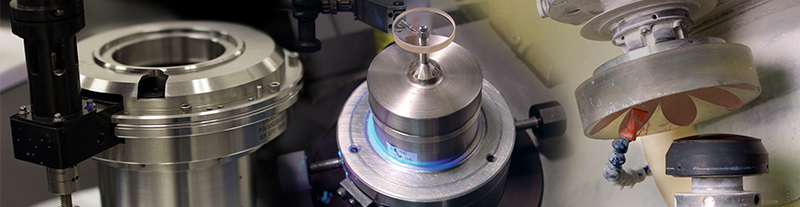

Fabrication & Polishing

Special Optics supports the complete production and assembly of prototypes and OEM systems. The entire process of lens manufacture, from rough grinding through polishing, edging and coating, is completed in-house. During the process, we closely monitor all phases of production allowing us to maintain precision tolerances in wavefront, thickness and surface quality. Our experienced team of fabricators and polishers work with a great majority of glass and crystal materials used in the optics industry.

The Process

We start with raw bulk glass which is cut and coredrilled to the appropriate diameter. Next the lens radius is cut into the surface using standard industry generators. Two grinding steps follow, first a rough 20 micron grit followed by a 9 micron grit fine grind. The lenses are now ready for polishing. Once blocking and polishing is accomplished, a final edging step is applied to bring the lens into final diameter and then correct any decentration or wedge between the lens surfaces.

Fabrication and Polishing Capabilities

-

Glass and Crystal Polishing

-

Precision Grinding and Polishing of Optics from 4 to 280 mm in Diameter

-

Over 1000 Test Plates on Hand

-

Surface Regularity Better than 1/20 Wave

-

10-5 Surface Quality

-

Interferometric Testing

-

Standard Radii from 2 to 13,931 mm

Next > Precision Assembly